Accueil | Our technologies > Thermoreactor®

THERMOREACTOR®

SUNKISS MATHERM invented the Thermoreactor® and was the first manufacturer in the world to innovative by developing an infrared technology specially adapted to drying, fusion and polymerisation of paint. SUNKISS MATHERM now designs and produces infrared drying tunnels for a variety of industrial applications. Benefits include saving times and space and achieving better product finishing, energy efficiency and greater operational flexibility.

3 ranges of infrared Thermoreactors® for your drying tunnel

AIRLESS RANGE

Low-power density infrared radiant unit- ideal for use on sensitive parts such as wood, plastic surfaces and so on

- operates in Gas mode

- temperature between 40°C and 100°C.

AIR BOOST RANGE

Medium-power density infrared radiant unit- highly energy efficient

- compact installation enables big energy saving

- temperature between 60°C and 250°C.

AIR RECYCLING RANGE

High-power density infrared radiant unit- highly energy efficient

- very environmentally friendly: it reduces VOCs and has an air cleaning system

- temperature between 70°C and 300°C.

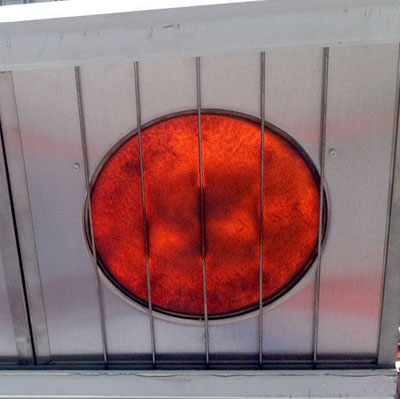

How does the Thermoreactor® work ?

T

he Thermoreactor® invented by Sunkiss Matherm is a radiant panel-style drying apparatus that uses gas catalytic combustion technology to produce infrared radiation. It transfers active energy to the very core of coating by sending electromagnetic waves across a very broad infrared spectrum. These waves constantly fluctuate and are absorbed perfectly into all organic coating (paint, glue, water, etc.).

Advantages

Primary benefit of the Thermoreactor® :

it saves drying time :

This radiant energy is augmented by the movement of reheated air at the surface of the Thermoreactor®, substantially reducing the time required for drying, fusion and polymerisation. The Sunkiss Matherm drying tunnel features special components, has a unique operating mode and stands out also for its infrared techniques. In addition, its radiation efficiency is amongst the best.

The industrial applications of SUNKISS MATHERM Thermoreactor®

S

UNKISS MATHERM’s infrared technology is renowned for its excellence for paint drying and curing but it also offers benefits to other industrial sectors that have similar requirements in terms of efficiency and quality.

| Examples of industrial application of the infrared radiant unit |

|---|

| Gelling plastisol |

| PVC foam expansion |

| Continuous glue drying on adhesive tape |

| Drying water-based sand moulds for foundries |

| Preheating plastic before jet piercing |